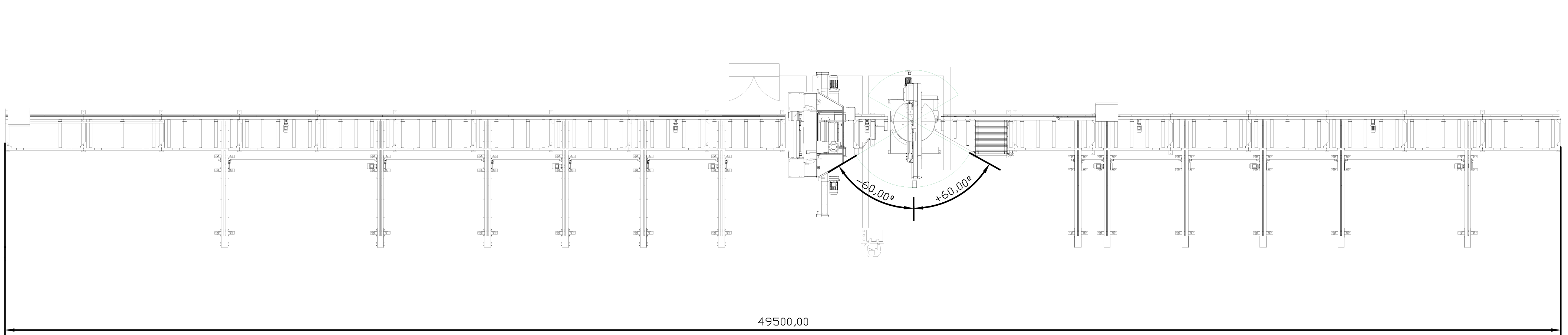

M&G is specifically designed for drilling and cutting bars, angles, and profiles

Oval drilling

M&G features vertical clamps that stabilize the materials, allowing precise drilling of oval holes.

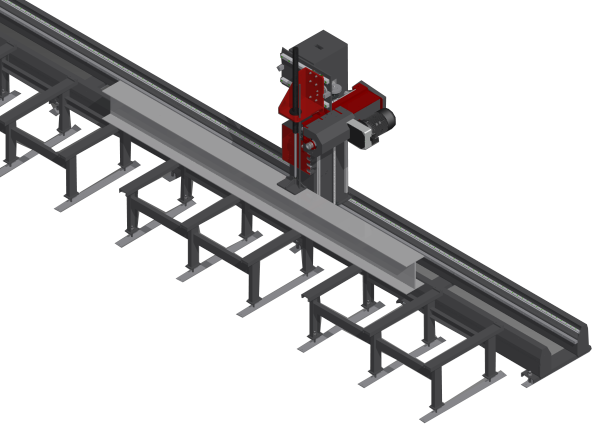

Innovative styling

The innovative design of M&G allows the machine to have a compact and highly efficient size.

Quick processes

The compact size reduces the axis movement times, consequently increasing the overall process speed.

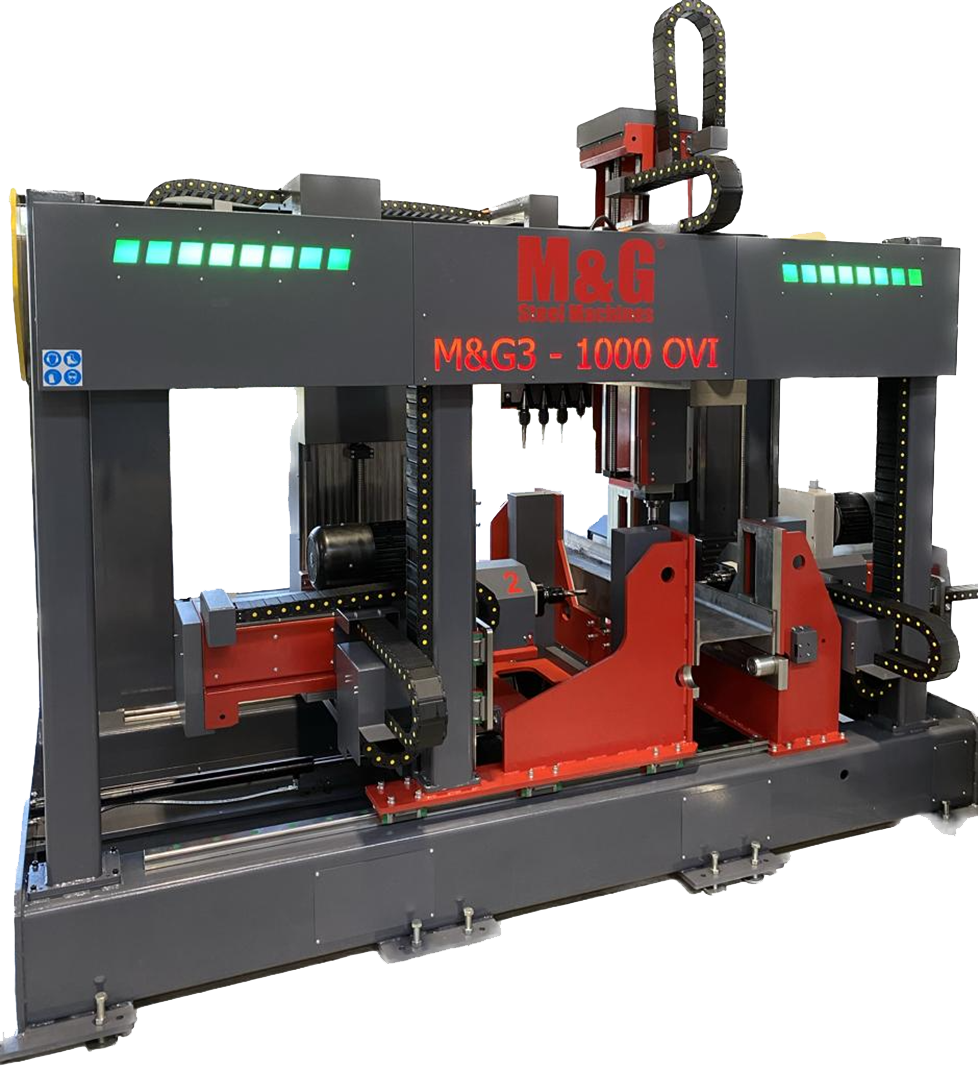

Automatic Tool Change

Each machine head has the option to automatically switch between 5 tools.

Drilling system

Este sistema oferece uma gama abrangente de operações, incluindo furação, roscagem, marcação e outras, com três cabeçais e controlo CNC.

Ideal para aplicações no setor da metalomecânica pesada de aço estrutural, este produto destaca-se pela sua versatilidade e capacidade de produção em larga escala.

Equipado com um sistema de medição avançado, que utiliza um empurrador com servomotor, este garante medidas precisas com tolerâncias rigorosas. Com três cabeçais capazes de furar até 40mm de diâmetro, esta linha oferece flexibilidade na escolha entre brocas de aço rápido e de metal duro, permitindo avanços de perfuração maiores.

M&G machines

M&G1 OV

M&G3 OV

M&G3 OVI

M&G Saw

Components

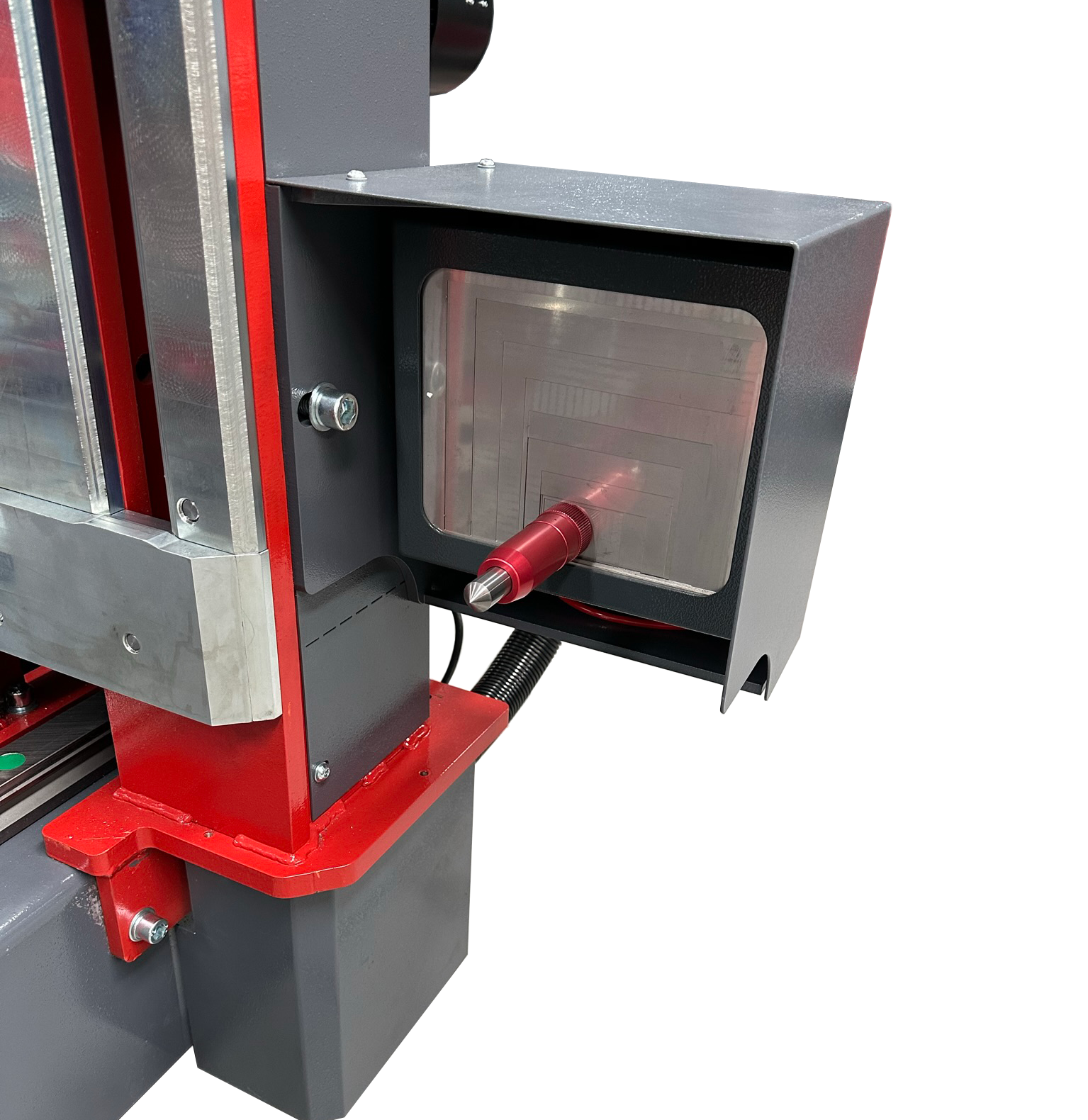

Part marking unit

It operates within a rectangular area of 120mm x 160mm, capable of writing identification without moving the material

The integrated controller allows you to change the depth and size of the character, ensuring that the marking is visible even with significant paint thickness

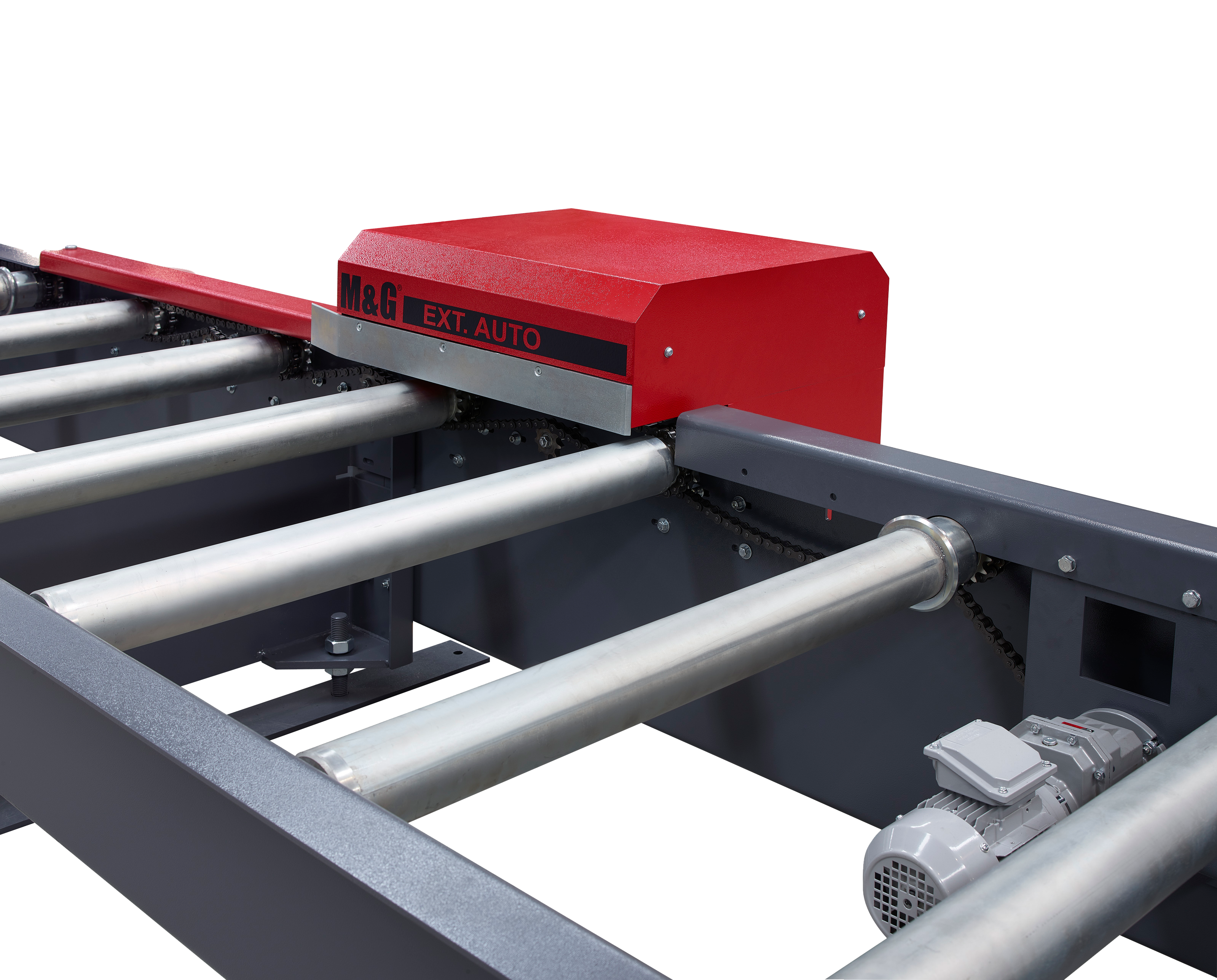

Automatic extractor

Table composed of a transverse metal conveyor belt, enabling the extraction of pieces ranging from a minimum of 40mm to a maximum of 1000mm